All equipment, whether new, serviced or repaired is subject to an extensive factory test under full load conditions by experienced test engineers to ensure compliance and maximum reliability.

We can provide a comprehensive repair, overhaul and maintenance service for the following range of equipment:

• Diesel and gas engines

• Air and gas compressors

• Blowers and vacuum pumps

• Industrial and marine generator sets

• Hydraulic power packs

• Electric and diesel engine driven pumping sets

• Electric and diesel engines and steam turbine driven

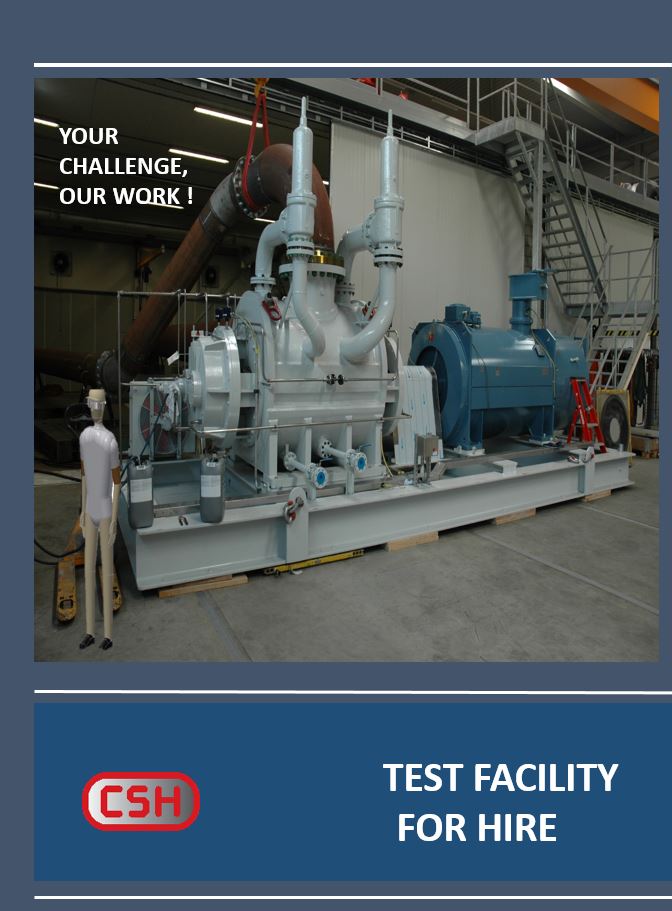

Test facility

The concrete test area floor is suitable for high loads and situated on top of a dedicated underground water reservoir of approximately 450 m³, with large diameter water test loop.

The large capacity water reservoir enables high power continuous running for prolonged periods without overheating.

For testing of vertical turbine pumps a deep well section of 8 m depth is available.

For testing of electrical motor driven equipment a 625 kVA diesel generator set is available.

For testing of PTO driven equipment a 500 kW diesel engine is available.

Testing Capability

We can perform cyclic and continuous full load testing of the following equipment:

• Diesel engine driven pump systems

• Lift pump / booster pump systems (string test)

• Hydrostatic driven pump systems

• PTO driven pump systems

• Electric driven pump systems

Water flow rates:

Up to 6.500 m³/hr and 40 Bar Up to 400 m³/m and 450 bar

NPSHa < 9.0 m (positive suction possible with feed pump)

Hydr. oil flow rates:

Up to 1.500 l/min

Up to 420 bar

Power ratings:

Over 3.000 kW (diesel engines)

Up to 450 kW / 400 V (in house available)

Higher electrical ratings possible 3/3.3 kV & 6/6.6 kV via transformers

Measuring and control equipment

Water flow meter: E&H Promag up to 200 m³/hr

ABB Watermaster up to 6.500 m³/hr

Viscous oil flowmeter : Up to 500 m³/hr x 24 bar

Hydraulic oil flowmeter: Webtec LT1500 flow meter up to 1500 l/min x 350 bar

Hydraulic oil load valve: Webtec HV1500 load valve up to 1500 l/min x 350 bar

Water control valve: ND500, hydraulic remote controlled

Pressure sensors: Various from -1 to 600 bar

Temperature sensors: Various 0-1500°C

Powerpack: Diesel driven hydraulic 240 l/min x 350 bar up to 1500 l/min x 350 bar as separate unit

Also possible to be carried out:

• Noise level measurement

• Vibration level measurement

Testing standards

We are able to test all equipment in accordance with worldwide International standards.

Miscellaneous

For your convenience we have a private office space available with Wifi connection and a meeting room for reception of your customer, third party inspector etc.

If you like to receive more information about the facility please mail us: rpn@compressorsystems.com.

The prices will be custom made.